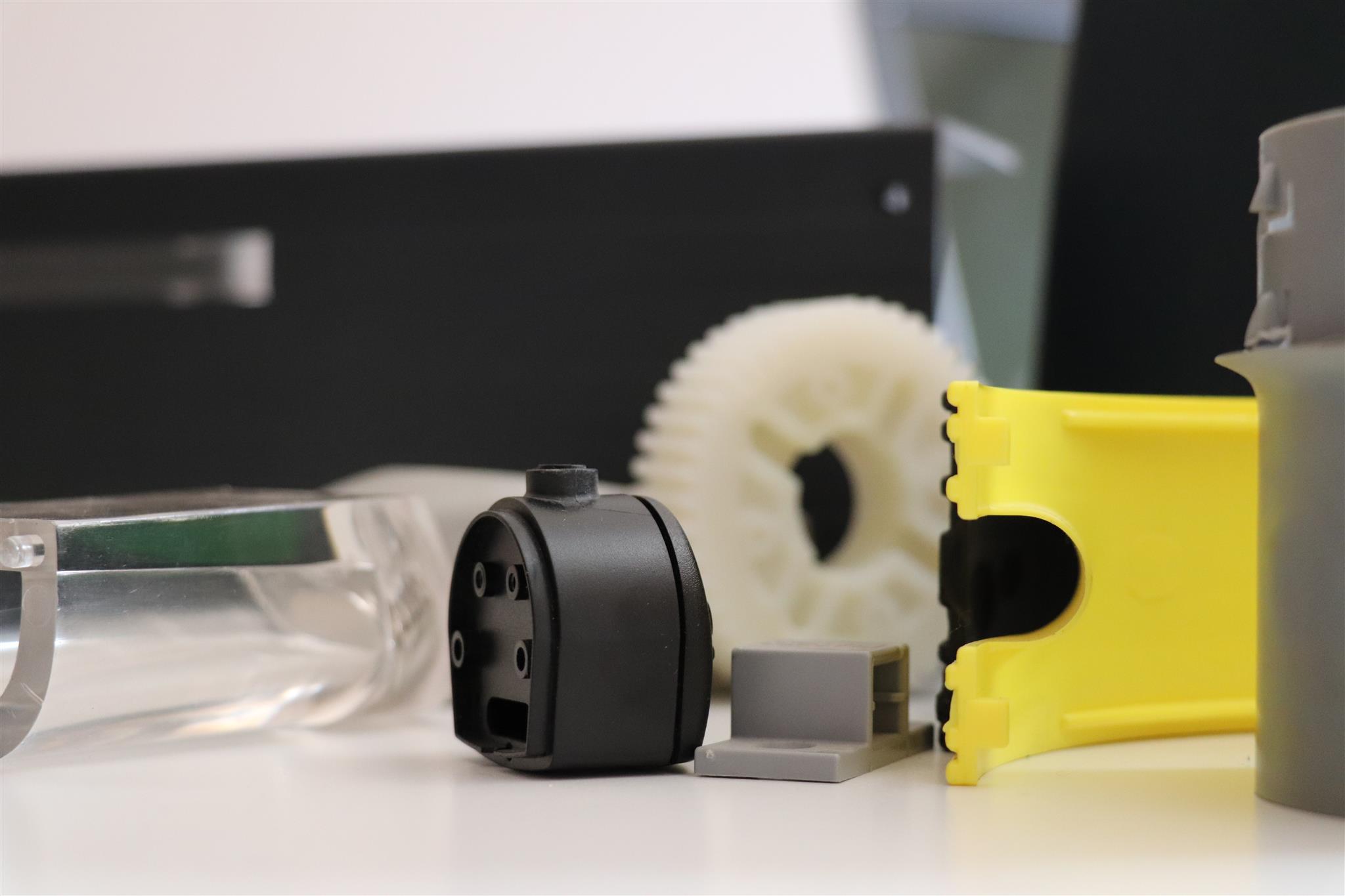

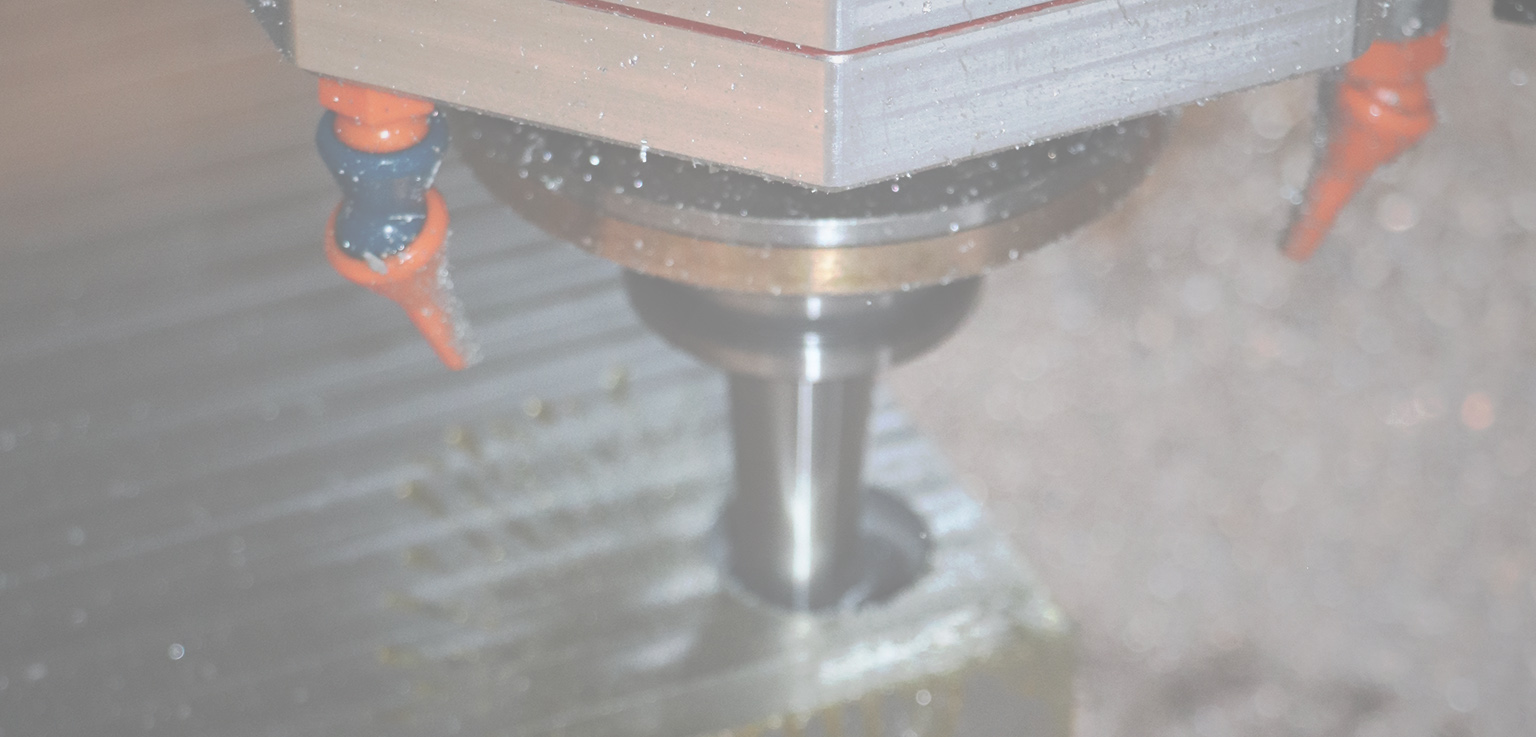

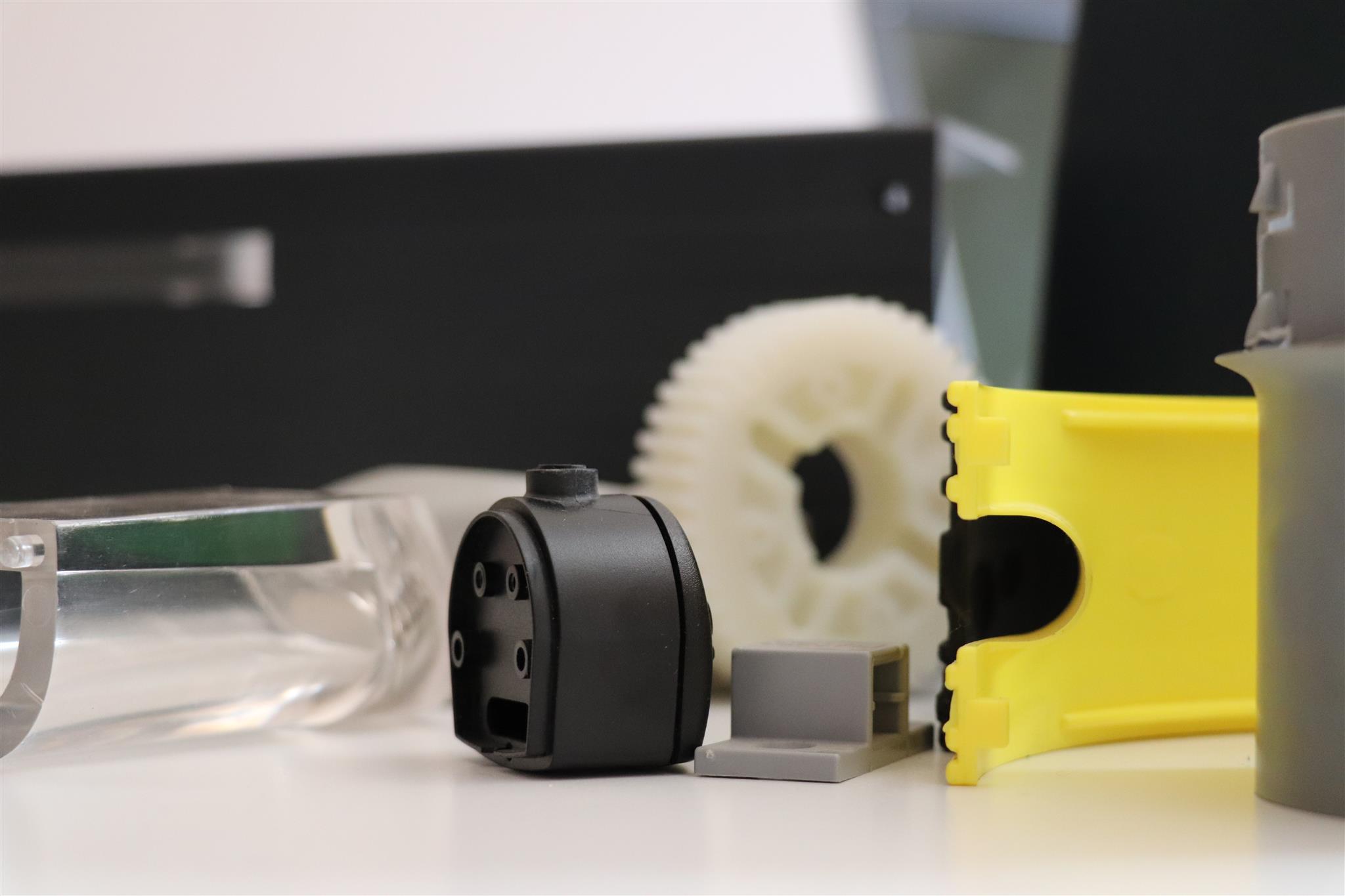

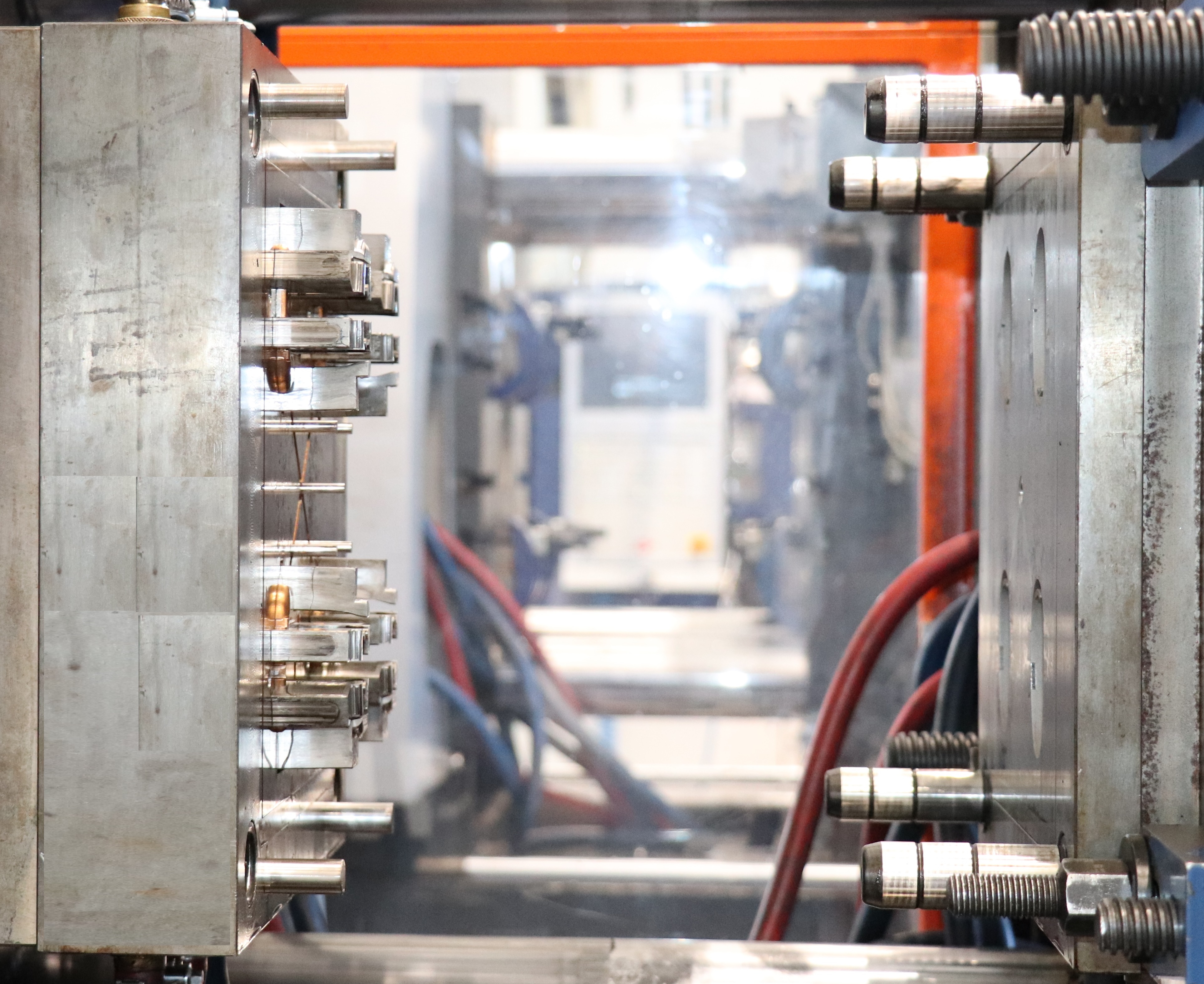

The activity of Plasting is focused on injection molding for third parties of various products used in the mechanical, electrical, manufacturing, domestic, military sectors. The production department consists of computer controlled presses from 6 to 320 tons, hydraulic and electrical of the last generation, for the molding of variable basis weight from 1 g to 1,200 g. assisted by Cartesian robot and specific machine tendings.

The molding department is equipped with automatic dehumidification and automatic mixing of materials and centralized granules transport. It is also possible to carry out co-injection, over-molding, sequential injection, molding of bi-color or bi-material, gas-assisted molding for the emptying of the material. Plasting is able to process different types of thermoplastic materials: from basic polymers (PP, PE, PS, ABS) to engineering plastics (PA, PC, PPO, POM, PMMA,) to special (TPU, POM, ABS / PA , PBT / PC) and thermoplastic and biopolymer elastomers. All the materials used for injection molding are certified at the source to guarantee high quality and extremely reliable printed products.

» » Our quality management system is certified by Rina Service SpA according to UNI EN ISO 9001: 2015.